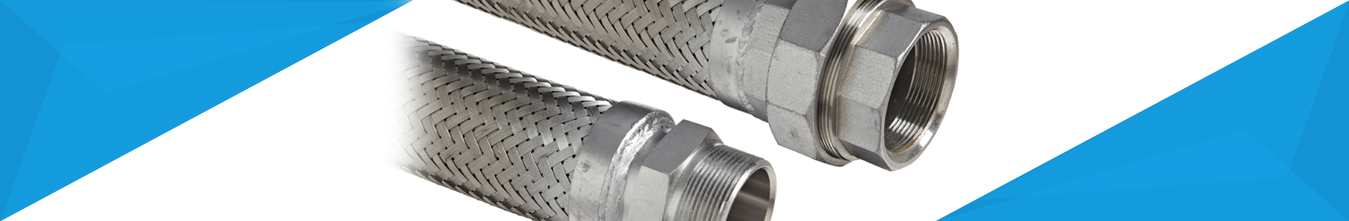

Stainless Steel Hose

Specification

BS 6501 / ISO 10380

Construction

Hose Material :

304/ 304L / 316 / 316L / 321

Braid Material :

Standard Braid Material is SS304, Other material on request like SS316.

Tube :

Heavy wall innercore or corrosive service. Butt welded Annular Corrugations, close- pitch tubing.

Size Range :

6mm I.D. to 900mm I.D.

Temperature :

- 200°C to 800°C for AISI 321 & 316 - 200°C to 420°C for AISI 304 & 304L

Application

This hose is suited for any application where working conditions demand one or a combination of any of the following : absolute leak proof, a high safety factor, extreme temperature, vibrations, high working pressure and corrosion resistance. Applicable for cryogenic and chemical transfer, vacuum, super-heated steam, coolant lines, fuel and oil burner lines, petroleum, refrigerants, gases, poisonous media and food stuff.

Hose Specification Chart

- I.D. inches

- I.D. mm

- O.D. mm

- Working Pressure kgf/cm2

- Test Pressure kgf/cm2

- Minimum bend radius mm

- 1/4

- 6

- 14

- 100

- 150

- 90

- 3/8

- 10

- 19

- 90

- 135

- 150

- 1/2

- 12

- 22

- 80

- 120

- 200

- 3/4

- 20

- 29

- 64

- 96

- 203

- 1

- 25

- 36

- 50

- 75

- 229

- 11/4

- 32

- 45

- 40

- 60

- 267

- 11/2

- 38

- 55

- 30

- 45

- 292

- 2

- 50

- 68

- 28

- 42

- 318

- 21/2

- 65

- 84

- 24

- 36

- 508

- 3

- 80

- 97

- 18

- 27

- 610

- 4

- 100

- 126

- 16

- 24

- 750

- 5

- 125

- 152

- 12

- 18

- 900

- 6

- 150

- 178

- 10

- 15

- 1050

- 8

- 200

- 225

- 8

- 12

- 1180

- 10

- 250

- 278

- 6

- 9

- 1250

- 12

- 300

- 330

- 5

- 7.5

- 1400

- For static pipe work, the bend radius can be reduced considerably.

- For extra high pressure, extra braid can be provided. Consult our Technical Department.

- For pressure drop estimates of corrugated metal hose, consult our Technical Department.

- The above pressure ratings are for fluid at ambient temp. of 30°C.

Temperature

As the operating temperature of a hose assembly increases, the maximum working pressure of the assembly decreases.

Below is a chart showing temperature correction factors for 'CONVOFLEX' Stainless Steel Metal Hose.

- (0C)

- Correction Factor

- (0C)

- Correction Factor

- -200 To 50

- 1.00

- 400

- 0.67

- 100

- 0.94

- 450

- 0.64

- 150

- 0.88

- 500

- 0.61

- 200

- 0.84

- 550

- 0.60

- 250

- 0.79

- 600

- 0.58

- 300

- 0.76

- 700

- 0.56

- 350

- 0.71

- 800

- 0.54

- Determine the maximum operating temperature of the application.

- Locate this temperature on the chart and read across to the proper factor.

- Multiply this factor times the maximum working pressure as determined from the Hose Specification Chart.

- This answer is your maximum Safe Working Pressure at that Elevated Temperature.

How to use Temperature Corrections Factor Chart?

Product Categories

- Stainless Steel Hoses

- Rubber Hoses

- XLPE HOSES

- Steam Hose

- Oil Suction & Discharge Hose

- Liquified Petroleum GAS (LPG) Hose

- Chemical Hose

- Phosphoric Acid Suction & Discharge Hose (GPS)

- Carbon Free Hose (GCF)

- Brewery & Cermery Hose (GBC)

- Cable / Furnace Coolant Hose (GFC)

- Air, Pneumatic, Rock Drill Hose

- Sand / Shot Blasting & Cement Grounting Hose (GSC)

- Sand and Gravel Hose (GSG)

- Water Suction Hose

- High Pressure Hydraullic Hose

- Composite Hoses

- PTFE Hoses

- Expansion Joints

- Flange Guards

- PTFE Lined Pipes & Fittings